CLASSIFICATION

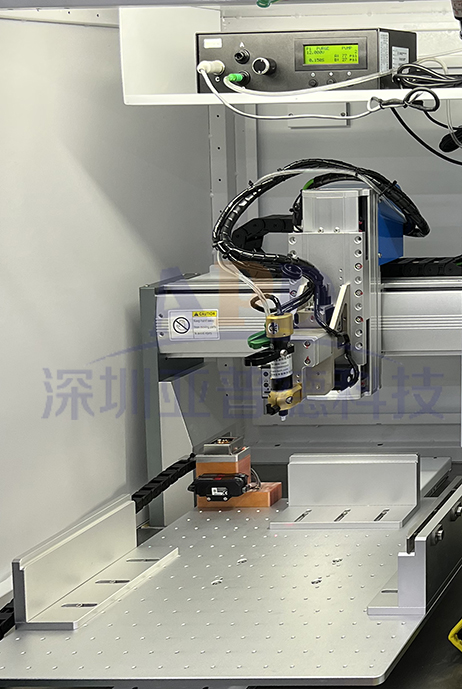

Precision solder paste coating system APD-2106

APD2106 is suitable for various types of BGA rework and can efficiently complete disassembly and assembly work.

Product features:

-

Floor standing, the platform adopts a unique mold integrated molding structure, the body is stable and solid, and the performance is more stable

-

CCD assisted programming and visual positioning, more convenient and efficient;

-

Optional laser height measurement system to reduce the impact of product deformation;

-

Optional automatic needle alignment system to ensure accuracy after needle replacement;

-

Windows 7 Chinese/English operating interface, easy to learn and understand;

-

It has functions such as continuous interpolation of points, lines, surfaces, arcs, circles, irregular curves, and three-axis linkage.

-

The intelligent controller adopts touch screen setting and operation, supports password permission control, digital air pressure and time output.

-

Supports wireless communication, Industry 4.0, and data exchange with MES system

-

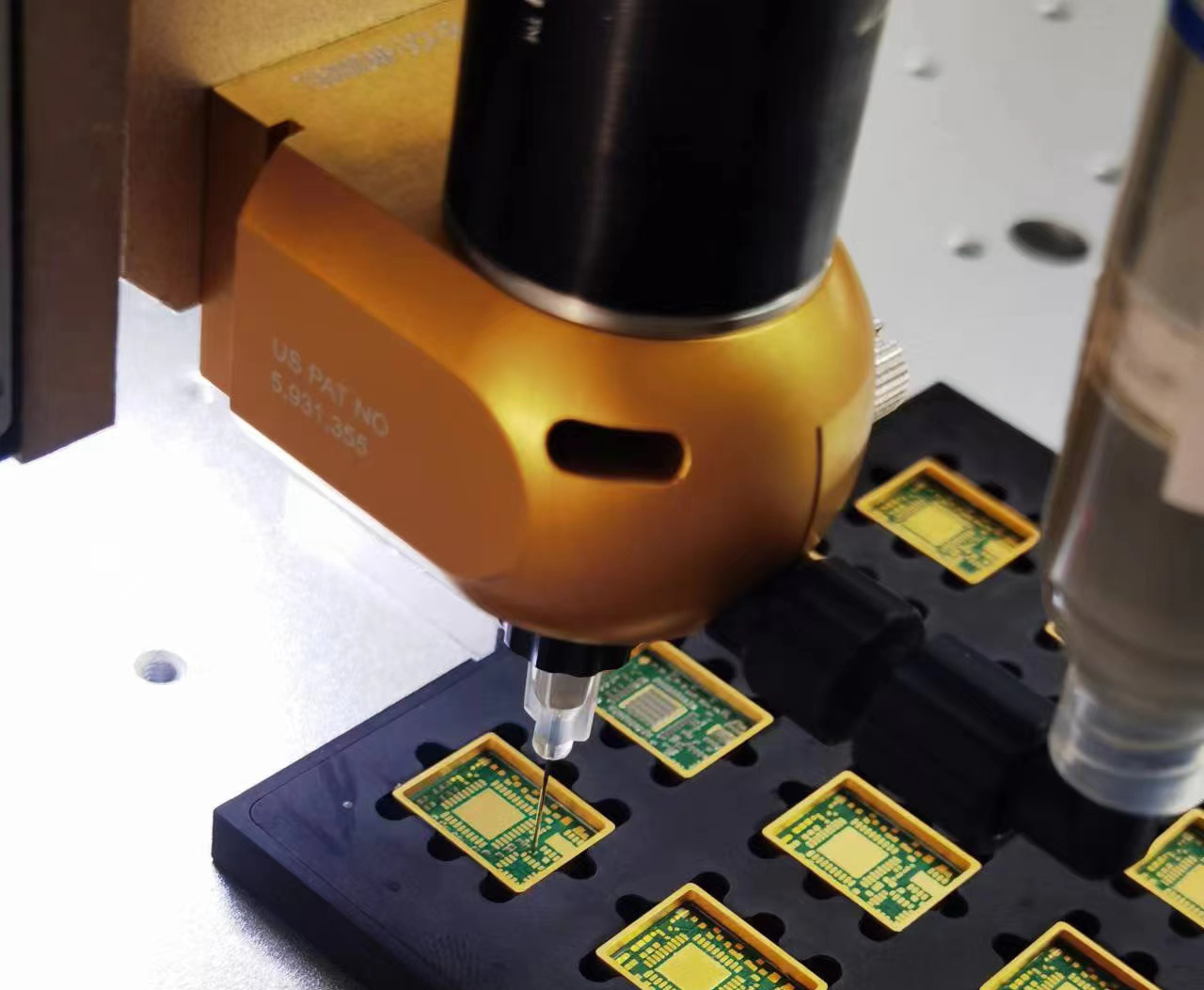

Precision screw valves are suitable for a wide range of adhesive viscosities, and the suction function ensures that there is no residual adhesive on the needle. The valve body does not require cleaning and maintenance, saving time and effort.

Partial parameter display:

XY speed: Max: 500mm/s

Transmission mode: servo motor/ball screw

XY acceleration Max: 0.8g Z velocity Max: 250mm/s Z acceleration Max: 0.3g

XYZ repeatability accuracy: ± 0.01mm

Vision: German high-definition digital camera (CCD)

Light source: LED red/blue/white light source

Valve: Screw valve

Maximum work schedule:500X *300Y*Z100mm

Platform specifications come standard with 350 * 350mm

The height of the work platform above the ground is 780 ± 20mm

Platform loadMax:15KgZ-axis load Max: 10Kg

Power requirement: AC220V, 50/60Hz, 2.5Kw

Pressure requirement 0.5-0.7Mpa, 0.2m 3/h

Machine volume L900 * W880 * H1600mm

Machine weight 350Kg